🧭 Scene-Setter: A Quarry Frozen Mid-Work

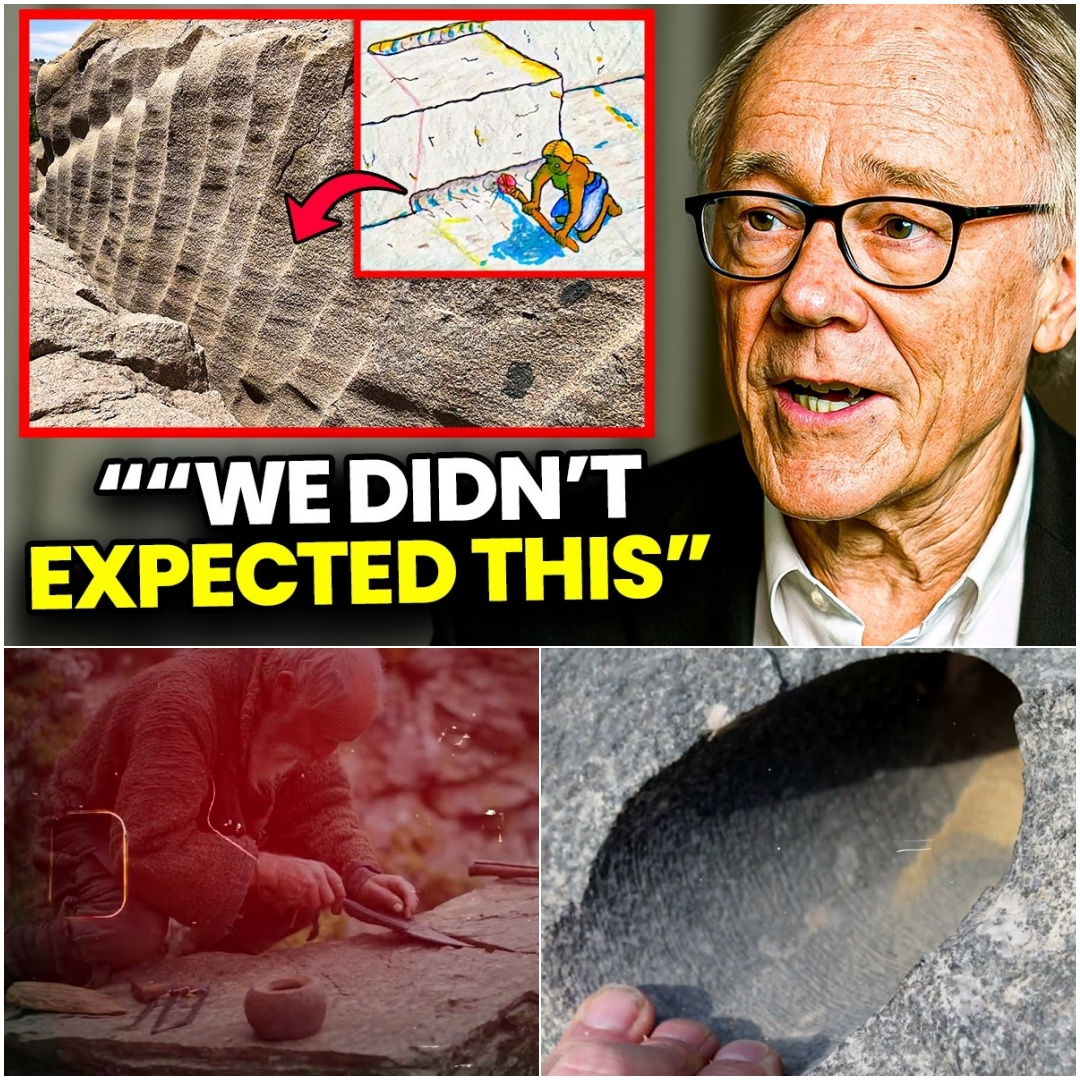

Stand at Aswan’s ancient quarry and the story hits you in the ribs. Beneath the unfinished obelisk—bigger than a jumbo jet, rooted in bedrock—you see them: smooth, perfectly curved scoops in granite. Not random chips. Not bruised stone. Elegant arcs that look like a machine kissed the rock and left. For years, the official line shrugged and pointed to copper chisels and dolerite pounders. But anyone who has ever swung a hammer at granite knows: those tools throw chaos, not choreography.

The tension has been building for decades. If ancient hands didn’t make those scoops with brute force, what did? Here’s a quick breakdown of the evidence, the failed explanations, and the hybrid technique that finally makes sense.

🔍 The Puzzle: Marks That Shouldn’t Exist

Those scoops aren’t shy. They repeat along channels, tuck into tight angles beneath massive stone, and keep their curvature with unnerving consistency.

- They appear under the unfinished obelisk, in places where force would be hard to apply and control even with modern gear.

- The interiors look polished, not torn—more “shaved” than shattered.

- The patterns flow like arcs from a guided arm, not the jagged scatter of pounding.

Engineers who’ve inspected the marks call them “deliberate.” Visitors call them “impossible.” Archaeologists, caught between both worlds, have been forced to ask the uncomfortable question: are we missing the real method?

🛠️ The Old Story Breaks Down

Why copper chisels and dolerite pounders don’t add up

- Copper is soft. Against granite, it blunts fast and cuts slow. Replication tests produce dents and shallow grooves—not those clean, concave scoops.

- Dolerite pounders bruise and chip. Their impact is chaotic, leaving jagged fractures, not smooth arcs.

“Granite doesn’t politely yield to copper,” says Dr. Jonas Reed, a materials engineer who has run field tests in Aswan. “You can mark it. You can exhaust yourself. You cannot sculpt those scoops with copper alone.”

Wooden wedges: clever, but not surgical

- The wedge method—hammer dry wood into slits, soak to expand—can split stone. It cannot carve uniform radii.

- Swelling is uneven. Fractures wander. The result is rough and unpredictable.

The quarry floor doesn’t show the mess this method tends to leave. It shows control.

⚙️ The Rotary Clues—and a Power Problem

Signs of rotation lurk in Egypt’s stonework: spiral tool marks on core samples, uniform grooves suggestive of spinning implements. Bow drills, weighted drills, and hollow tube drills with abrasive slurries can do surprising things to hard stone.

- Copper tube + quartz sand slurry can drill clean circular holes.

- Weighted drills add constant pressure, improving consistency.

But here’s the rub: torque and stability. Human-powered systems struggle to deliver the speed and sustained contact needed for those deep, identical scoops—especially under an embedded monolith.

“Some patterns look like machine work,” notes Prof. Amira Saleh, an archaeologist who studies quarry techniques. “But the power budget doesn’t fit a fantasy machine age. The marks suggest guided motion—yes. Not industrial horsepower.”

🔬 The Breakthrough: Heat, Abrasives, and Guided Scraping

The turning point came when researchers stopped trying to “cut” granite and started trying to “weaken” it.

The hybrid technique in plain terms

- Controlled heating: Fire warms the granite surface, inducing micro-fractures and internal stress.

- Rapid cooling with abrasive slurry: Water mixed with quartz sand (or emery) penetrates those tiny cracks, widening and embrittling the surface layer.

- Guided scraping: A tool embedded with harder minerals scrapes away the now-brittle outer skin in smooth arcs, pass after pass.

This isn’t brute carving—it’s stone conditioning followed by precision removal.

- Microscopic analysis of scoop interiors shows fractured, eroded surfaces rather than pure cut faces.

- Residues in some grooves include crushed quartz and signs of thermal alteration—fingerprints of the method.

- The consistent radius and depth can be explained by a guided arm or frame maintaining path and pressure, not by freehand blows.

“In materials terms, they were turning granite into a layered cake,” says Dr. Reed. “Stress the crust, saturate it with abrasives, then shave. Repeat. That’s how you get those arcs—clean, smooth, consistent.”

🧰 Rethinking the Tool Team

Under the hybrid model, the usual suspects don’t vanish—they change jobs.

- Dolerite pounders: Secondary role. Knock loose weakened fragments after scraping, not shape the curves.

- Copper tools: Frames, fittings, and holders for abrasive inserts—adaptable supports rather than primary cutters.

- Wooden wedges: Assist separation along natural fissures after the surface is conditioned—not the star of the show.

- Weighted drills and tube drills: Specialized tasks where rotation and slurry excel—holes, channels, and finish work.

“Each tool isn’t the hero,” says Prof. Saleh. “The workflow is the hero. Fire to stress, water and sand to infiltrate, guided scraping to sculpt, pounders to tidy, wedges to part. It reads like a well-run shop, not a miracle.”

🧪 Why This Fits the Quarry—and the Culture

- The method explains the lack of huge debris piles: most removal was fine dust and granular waste carried off naturally.

- It matches other ancient mining practices where controlled fire-setting and abrasives are documented.

- It scales to the administrative reality: skilled teams working within plausible timelines, not multigenerational mega-labor.

It also reframes the Egyptians: not as tireless pounders, but as pragmatic engineers. They mastered rock behavior, exploited heat and stress, and used abrasives like a surgeon uses a scalpel.

🧯 Expert Voices: From “Impossible” to “Inevitable”

- Dr. Jonas Reed, materials engineer: “When you stop asking granite to be carved, and start asking it to be conditioned, the scoops stop being mysterious and start being inevitable.”

- Prof. Amira Saleh, archaeologist: “We keep looking for metal to blame or a machine to worship. The evidence points to process—thermal, chemical, mechanical—used in a disciplined sequence.”

- Lara Quinn, quarry historian: “The elegance of those arcs isn’t magic. It’s muscle guided by method. The marks are signatures of a routine, not of a miracle.”

📊 Quick Reality Check Table

A short snapshot to separate romance from the rock record.

| Claim | What the evidence supports | What it doesn’t |

|---|---|---|

| Scoop marks from brute pounding | Secondary cleanup by pounders | Primary shaping of smooth arcs |

| Copper chisels as main cutters | Copper as frames/holders for abrasives | Fast, clean cutting of granite faces |

| Wooden wedges made the curves | Assisted separation after conditioning | Uniform radii and polished interiors |

| Lost advanced machines | Guided motion, weighted/rotary aids + abrasives | Industrial-level torque and metal tooling caches |

Bottom line: not sci-fi machinery—smart physics, smart abrasives, smart guidance.

💡 Why This Discovery Matters

- It rehabilitates ancient know-how: the Egyptians weren’t defying physics; they were using it.

- It offers a sustainable blueprint: low-energy, high-precision methods that modern stonework can learn from.

- It cleans up the narrative: the quarry becomes a controlled workshop, not a battlefield of broken rock.

The key takeaway here is simple and satisfying: those scoop marks weren’t mistakes or mysteries. They were the signatures of a hybrid technique—heat to stress, sand to infiltrate, guided tools to shave—that turned the hardest granite into obedient curves.

🚀 Final Word: The Day the Quarry Started Making Sense

The unfinished obelisk still lies there, mid-sentence. But the punctuation—the scoops beneath it—finally reads. Ancient engineers conditioned the granite, then sculpted it with precision, pass by pass, arc by arc. No magic. No machines beyond simple, clever rigs. Just a civilization fluent in natural forces and patient enough to let physics do the heavy lifting.

Archaeologists have, at last, sketched the method that makes those marks possible. And once you see it, you can’t unsee it: the quarry isn’t a mystery anymore. It’s a masterclass.